|

|

|

|

|

|

Click

Here for Printable Version

Click

Here to View as Web Page

Quick Content Links

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TriMark History in Logos

|

|

|

|

As TriMark has

grown and changed, the logo that represents the TriMark brand has

evolved with the times.

|

|

|

|

Special Products for Special Vehicles

|

|

|

|

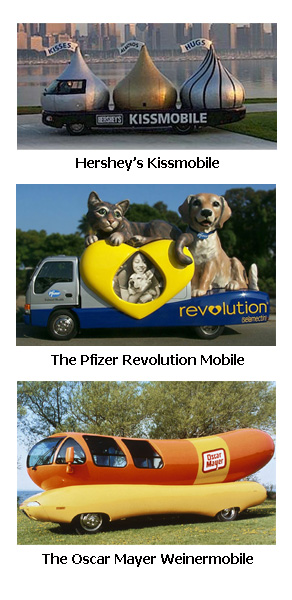

In

addition to TriMark Service and Replacement Parts providing original

hardware products and keys to RV dealers, locksmiths, and various

end-users, TriMark has also been involved with providing

"Access Solutions" for some highly visible and recognizable

specialty vehicles.

Do you recognize these marketing icons?

TriMark's 40 Year Presence at Top

Industry Tradeshows

|

|

|

|

TriMark "Access

Solutions" Stand the Test of Time

|

|

|

|

For

anyone who does not believe that good product design can endure and even be

improved upon, they just need to take a closer look at some of TriMark's

legacy products which are the "grandfathers" of many of today's

successful systems and products.

The 718 Series Two Rotor Latch was originally developed in 1975, was the

foundation for our popular 050-0100 Two Rotor Latch. Over 10 million units

sold, this proven robust latch fits a wide range of applications and

markets. The 2000 Series Elixir Door Latch was first introduced in 1978 and

is still sold today as a 060-0251 Trailer Latch. This product was one of

the first to have an integrated plunger latch in a paddle. The photo below

is one of the first prototypes that were hand crafted, tested and marketed.

The 710S Series Compartment latch is still sold to Caterpillar as a

030-0150 Heavy Duty Compartment Latch, and was the first integrated paddle

and rotary latch. And finally the 731 Series Flush Paddle still lives on as

a 030-0200/0250 Paddle Handle for the demanding needs of forestry and

construction equipment.

TriMark's rotary latch product line (20 million produced and still

counting!), a variety of paddle handles and latches these products have

all helped create and sustain TriMark's reputation for innovative

mechatronic door access systems.

|

|

|

|

|

|

|

|

APTA

Expo 2011 (Transportation Show)

October 3-5, 2011

New Orleans, LA.

AUSA

Annual Meeting and Exposition (Armored Vehicle)

Oct. 10-12, 2011

Washington Convention Center, Washington, DC

BICES

2011

Oct. 18-21, 2011

Beijing Jiuhua International Exhibition Center

Beijing, China

2012

National RV Trade Show

Nov. 29 - Dec 1, 2011

Kentucky Expo Center

Louisville, Kentucky

|

|

|

|

|

|

|

EDITOR'S NOTE: If

you would like to send a copy of this e-newsletter to a friend, colleague

or associate, the Send to a Friend link at the bottom of this

newsletter is a convenient method for providing them with their own

personal copy.

|

|

|

|

|

Looking Ahead While Looking Back

|

|

|

|

As I was thinking about my message to you for this special

issue of the TriMark e-newsletter celebrating TriMark's 40th

Anniversary, I was suddenly struck by a "reality check" how do

40 years fly by so quickly? While not the first employee, I can tell you

that I am in the "Top Ten" so I've had a very good seat from

which to see TriMark and its predecessor companies grow and change

as the times and our customers have dictated. While hindsight is always

20/20, I can say that as a company we've always tried to do the right thing

for customers and for our employee/owners. As I was thinking about my message to you for this special

issue of the TriMark e-newsletter celebrating TriMark's 40th

Anniversary, I was suddenly struck by a "reality check" how do

40 years fly by so quickly? While not the first employee, I can tell you

that I am in the "Top Ten" so I've had a very good seat from

which to see TriMark and its predecessor companies grow and change

as the times and our customers have dictated. While hindsight is always

20/20, I can say that as a company we've always tried to do the right thing

for customers and for our employee/owners.

I'm sure you've noticed in your business how quickly the technology changes

as it always seems to be a bit of struggle to keep up with the latest and

greatest. While we were combing the archives for information for this

newsletter, we thought it might be fun to share with you some of the

information we dug out from the "old days." For example, we ran

across a story that Ric Marzolf, VP of Research and Development, wrote for

our internal newsletter back in 2002. He was reflecting on the changes that

had taken place in our Engineering Department during his first 25 years

with the company. We thought it would be fun to include that story for you.

How many of you remember the slide rule?

We also took some time to talk with some of the long-time employees about

the changes they've witnessed during their time at TriMark. In

addition, we dug deep into the archives and found some photos of some very

special and high-visibility product applications (see Special Vehicle

story) TriMark has been involved in through the years.

While we take this time to look back 40 years and reflect on the road we've

taken to this point, we also have to look at our company GPS (there's a

term you didn't hear 40 years ago!) and plot the course for where we want

to go in the future. The TriMark team continues to push forward its

commitment to providing effective access solutions for our global

customers.

While you and I will probably not be around for TriMark's 80th

Anniversary, won't our successors have fun laughing at our

"ancient" technology? Thank you for your continued support of TriMark

nothing happens without our dedicated employees, dependable suppliers and

great customers!

Patti Knowlton

General Manager

|

|

|

|

TriMark Celebrates 40 Years of Door and Access

Hardware Innovation

|

|

|

|

TriMark,

a global designer and manufacturer of quality hardware products for the

recreational vehicle, agricultural, truck, construction, and industrial

enclosure markets is celebrating its 40th anniversary this year.

In 1971, TriMark Corporation was founded in New Hampton, Iowa with

humble beginnings as a tool and die shop. The original owner had a vision

to automate the die cast and assembly process supporting the window

hardware market. Since then we have grown on the basis of the Midwestern

work ethic, engineering excellence, product quality and a drive to serve

customer's needs with products that fit THEIR requirements, especially when

that meant innovation, problem solving and a customized solution.

In 1975, TriMark developed a heavy duty rotary latch

for Winnebago Industries motor homes and Caterpillar construction

equipment. This product line was the foundation for the popular 050-0100

Two Rotor Latch that is still sold today and was the beginnings of the

current vehicular door hardware product line. TriMark has been

recognized as a real product innovator with multiple patents as well as

many unique and exclusive features. We like to say that TriMark

rotary latches are "Often Copied but Never Equaled." In 1975, TriMark developed a heavy duty rotary latch

for Winnebago Industries motor homes and Caterpillar construction

equipment. This product line was the foundation for the popular 050-0100

Two Rotor Latch that is still sold today and was the beginnings of the

current vehicular door hardware product line. TriMark has been

recognized as a real product innovator with multiple patents as well as

many unique and exclusive features. We like to say that TriMark

rotary latches are "Often Copied but Never Equaled."

Today TriMark offers the widest range of rotary

latches and leads the industry in reliability and durability. Products

range from basic stand-alone designs to integrated linkages for both FMVSS

206 (Federal Motor Vehicle Safety Standard for Door Locks and Door

Retention Components) and non-206 applications. Offering a broad selection

of rotary latch sizes, versions, features and options to meet virtually any

application, all TriMark rotary latches feature the highest levels

of quality, security and strength. Today TriMark offers the widest range of rotary

latches and leads the industry in reliability and durability. Products

range from basic stand-alone designs to integrated linkages for both FMVSS

206 (Federal Motor Vehicle Safety Standard for Door Locks and Door

Retention Components) and non-206 applications. Offering a broad selection

of rotary latch sizes, versions, features and options to meet virtually any

application, all TriMark rotary latches feature the highest levels

of quality, security and strength.

In 1989 TriMark employees added the pride of ownership to their

motivation by purchasing the company and becoming 100% employee owned. Over

the years, we've grown from ten employees to more than 300.

Our New Hampton facility is the corporate headquarters and

is sited on twelve acres providing 132,000 square feet of administrative,

engineering, manufacturing, service, and support activities. Our New Hampton facility is the corporate headquarters and

is sited on twelve acres providing 132,000 square feet of administrative,

engineering, manufacturing, service, and support activities.

In 1997, TriMark Europe was incorporated as a sales, engineering,

distribution and logistics facility supporting the European construction

equipment market. TriMark Europe is located at Bardon Hill,

Coalville, United Kingdom. In 2007, TriMark Europe Ltd, a subsidiary

of TriMark Corporation, has acquired West Alloy Ltd. Located in the

UK. West Alloy is a market leader in the design and manufacture of locks,

hinges, window stays and associated fittings for the world's best-known

industrial and leisure vehicles.

In 1999, TriMark Service and Replacement Parts Division was launched

and is located in a 9,600 square foot facility in New Hampton, Iowa.

Providing the original hardware products and keys to RV dealers,

locksmiths, specialty vehicle users and end users, we support "just-in-time",

repair part packaging and stocking programs. Technical staff can assist in

the proper selection and application of our products and help with the

identification of repair or service parts.

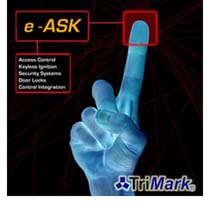

In 2003 TriMark

launched e-ASK electronic Access and Security Keyless-entry

product line consisting of RF transmitter FOBs, keypads, I/O modules, power

lock actuators and a wide variety of accessories for electronic products.

Our keyless access control systems pave the way for innovative technologies

that make non-automotive vehicles more convenient and secure. In 2003 TriMark

launched e-ASK electronic Access and Security Keyless-entry

product line consisting of RF transmitter FOBs, keypads, I/O modules, power

lock actuators and a wide variety of accessories for electronic products.

Our keyless access control systems pave the way for innovative technologies

that make non-automotive vehicles more convenient and secure.

One of TriMark's strategic strengths is the ability to provide

complete door systems. Our broad product line includes handles, latches,

strikers, rods and accessories, key cylinders, actuators, ignition

switches, key pads and FOBs, CAN I/O modules, and door kits. And because

today's applications are increasingly integrating mechanical systems with

electronics and computer controls, TriMark has dedicated itself to

being the undisputed leader in mechatronic integration of access systems

for personnel doors, access panels, engine compartments and hoods, interior

compartments, windows, and vehicle controls.

Following the global shift of construction equipment

manufacturing, in 2007 TriMark obtained its license to manufacture and sell

in China under the name TriMark (Xuzhou) Automotive Components Co.

Ltd. in Xuzhou, China. Caterpillar and John Deere are two well known global

customers that are served from TriMark China as well as a host of

domestic customers in the China construction market. Following the global shift of construction equipment

manufacturing, in 2007 TriMark obtained its license to manufacture and sell

in China under the name TriMark (Xuzhou) Automotive Components Co.

Ltd. in Xuzhou, China. Caterpillar and John Deere are two well known global

customers that are served from TriMark China as well as a host of

domestic customers in the China construction market.

In 2008, TriMark established the Armored Vehicle Business Unit that

is dedicated to serving the needs of key armored vehicle OEM's as well as

the commercial security market. Offering security, reliability and modularity,

the TriGuard line of TriMark's heavy duty latches, linkages, handles

and door modules are specifically developed for heavy duty armored vehicle

applications. These robust door product/systems simplify vehicle and field

attachment with reduced attachment points and door assembly.

Product quality is the primary driver of TriMark

product engineering and its manufacturing processes. The emphasis on high

quality persists throughout a worldwide supply base as suppliers are

selected, not based on price, but the ability to deliver what TriMark

is expected to provide; safety, quality, reliability, value and pride of

ownership. Product validation is handled in TriMark's world class

testing laboratory, which is able to accelerate harsh operating

environments. Salt spray, dust chamber, lifecycle, and strength testing are

performed to validate and further compress the time needed to launch the

entire door system. Product quality is the primary driver of TriMark

product engineering and its manufacturing processes. The emphasis on high

quality persists throughout a worldwide supply base as suppliers are

selected, not based on price, but the ability to deliver what TriMark

is expected to provide; safety, quality, reliability, value and pride of

ownership. Product validation is handled in TriMark's world class

testing laboratory, which is able to accelerate harsh operating

environments. Salt spray, dust chamber, lifecycle, and strength testing are

performed to validate and further compress the time needed to launch the

entire door system.

Customers soon discover TriMark works even harder after the order is

placed to insure that the logistics of supply remain consistent and

communication open. Customer service representatives are available to

immediately answer questions for clients that experience fluctuations in

their manufacturing.

We are the industry leader in the design, manufacture, and supply of door

latch systems. Our years of experience provide us with a special knowledge

that goes far beyond the simple function of opening and closing a door.

Applications experience encompasses access systems for personnel doors,

access panels, engine compartments and hoods, interior compartments,

windows, and cab and vehicle controls.

TriMark's customers are found in a diverse set of both on-road and

off-road applications such as industrial enclosures, power sports, mass

transit, armored vehicle materials handling, utility truck, fire and

rescue, heavy truck, special purpose vehicles, RV, bus, and motorcoach,

agricultural equipment, and construction equipment. Not surprisingly, many

of the markets are global in nature. And for that reason, TriMark

has not ignored the need to integrate itself into the global marketplace.

Building on 40 Years of Innovation

Together with key factors that characterize the company's

history: innovation, application engineering, product performance, Together with key factors that characterize the company's

history: innovation, application engineering, product performance,

mechatronics, motivated employees and excellence of sourcing and

manufacturing coupled with a market focus and future global trends will

enable TriMark Corporation to face the future with renewed

confidence and expectation of success.

To share this article with a friend or colleague, please use the Send

to a Friend link at the end of this newsletter.

|

|

|

|

Ric Remembers

|

|

|

|

Back

in 2002, Ric Marzolf, TriMark's Vice President of Research and Development,

wrote an article for TriNews, TriMark's internal company

newsletter, reflecting on his 25 years with the company. We thought our

readers might find it interesting to see what he had to say at that time

about the changes he experineced during that quarter-of-a-century. In honor

of the 40th Anniversary, he agreed to give us an update on what's changed

since that 2002 article appeared.

TriNews 9/02

2002 is a milestone year for me; I attended my 30th High

school reunion, reached my 25th anniversary at TriMark in August and

recently celebrated 20 years of marriage. The cars I drove and the music I

listened to (still do) are now considered classics. All of this of course

dates my age, but I wanted to reminisce briefly about the changes I have

seen at TriMark's product development going back to the good old

days (kind of sounds like my parents doesn't it?). 2002 is a milestone year for me; I attended my 30th High

school reunion, reached my 25th anniversary at TriMark in August and

recently celebrated 20 years of marriage. The cars I drove and the music I

listened to (still do) are now considered classics. All of this of course

dates my age, but I wanted to reminisce briefly about the changes I have

seen at TriMark's product development going back to the good old

days (kind of sounds like my parents doesn't it?).

Drawings were done in pencil on a drafting table or board hence the term "It's

on the board" (in development) or "back to the drawing

board" (major revisions required). Tools that were used in the

drafting function included drafting machines, scales, compass, templates,

triangles, and electric eraser/erasing shields to correct the mistakes. You

can imagine the time and expense to redraw a drawing or move a detail a

mere .250 in.

Project notes, meeting minutes and a lot of calculations

were hand written on lined paper. Slide rules were used for computations,

including multiplication, division, powers, roots and trigonometric

functions with the first calculators being used in 1975. Mine was a Texas

Instruments TI-1250 and cost $60 for a basic four-function model. Project notes, meeting minutes and a lot of calculations

were hand written on lined paper. Slide rules were used for computations,

including multiplication, division, powers, roots and trigonometric

functions with the first calculators being used in 1975. Mine was a Texas

Instruments TI-1250 and cost $60 for a basic four-function model.

TriMark's Product Development process has gone thru a total of 3

major programs PDG, Flexibility, and the current P3 process plus

continuous improvements and updates for each. Prototypes were crude,

costly, took a long time and were done toward the end of the development

cycle. The tolerances were atrocious and a great deal of fine-tuning was

involved to get them to work the way they should. I have one of the first

Travel Trailer prototypes (Elixir Lock) from 1977 in my office. By

comparison our new Stratasys FDM (Fusion Deposition Modeling) rapid

prototype machine is more akin to a copy machine than the DTM SLS sinter

station machine we previously had and it light years ahead of the rubber

molds and machined prototypes. It will offer us better accuracy, faster build

times and more robust parts. >

> Click here to continue...

To share this article with a friend or colleague, please use the Send

to a Friend link at the end of this newsletter.

|

|

|

|

TriMark Employee Memories

|

|

|

|

While it may not

be totally unique to a company celebrating 40 years in business, TriMark

enjoys having a relatively large percentage of its employees who can trace

their history with the company back over 30 years. We thought it would be

fun to hear what they have to say about things such as the biggest changes

they've witnessed and some of the other memorable moments that make this

employee-owned company a real family.

When we reached out to about 30 TriMark employees

who've been with the company 30+ years, we weren't really sure just what

information we would get back in response to our questions. Here are a few

highlights we thought you might enjoy. We have not included the names to

protect the innocent! When we reached out to about 30 TriMark employees

who've been with the company 30+ years, we weren't really sure just what

information we would get back in response to our questions. Here are a few

highlights we thought you might enjoy. We have not included the names to

protect the innocent!

Question: What is the most significant change in the company that you

can remember?

Most of those who answered this question mentioned the increased use of

technology computers and automation - throughout all company operations.

"When we decided to replace our first computer with an

AS400 we went from a computer the size of a chest freezer to one the size

of a dehumidifier. Of course the machine was more money and I can still

remember Scott Perkins coming in to see it and asking me where the rest of

it was." "When we decided to replace our first computer with an

AS400 we went from a computer the size of a chest freezer to one the size

of a dehumidifier. Of course the machine was more money and I can still

remember Scott Perkins coming in to see it and asking me where the rest of

it was."

Also, the 1989 Employee Stock Ownership Plan, which accompanied the buy-back

of the company, was very high on most respondents list. This answer also

was listed by several respondents when asked about their most memorable

moment at TriMark.

The following was written for a capabilities brochure in 1990 as the

kick-off to becoming Employee Owned

.

A strong work ethic has long been a valuable asset for businesses that

locate in the nation's heartland. At TriMark, it's taken for granted.

Our employees, some 115 strong, represent average work tenure of over 10

years. Yet even with all this experience, we're a young company with an

average age of only 35 years. When you take these employee's

characteristics and consider these employees actually own the company, it's

not difficult to understand why a commitment to quality and service are

taken very seriously. Our pride runs deep. And it shows in our products.

Because we're an employee-owned company we think it's critical to do things

right the first time every time! Should we ever fail to meet the

expectations of our customers, you can be assured we will make it right. We

have more than our jobs on the line here we have our word. And in New

Hampton, Iowa, a person's word isn't just a hollow statement, it's a pledge

and we stand behind it every single one of us.

Today, after 22 years of ESOP, we've grown to 267 employees in the ESOP

and have average work tenure of 12 years with an average age of 44. So we

have matured a little and are proud that we have 30 employees with over 30

years experience that are still delivering on the promises that have

propelled TriMark to where we are today. Today we are welcoming new

employees that have the kind of skills and training demanded companies such

as TriMark who operate on a global stage. We welcome these new

additions to the TriMark family and look forward to seeing them

continue on the successful path that has provided TriMark the keys

to success for our first 40 years.

The addition of TriMark Europe and TriMark China was also

mentioned.

Question: How would you describe your experiences at TriMark?

We'll use this direct statement to speak for a majority of the respondents:

"Well, I love what I do and I guess when you can still wake up and

look forward to going to work, that's a good thing."

Question: Do you have any other comments you would like to share?

"Thirty-five years ago, I was on my way to Waterloo, Iowa to look for

a job. I was going past TriMark and though I would stop. I had an

application in already. Jim Grove, then the supervisor of Die Cast talked

to me and said, "A guy quit in Die Cast this morning, you can start

Sunday night on third shift." I thought well I can do this till I find

something better. Well I'm still here

"

And finally.

"I have never met someone from outside of TriMark who didn't

want to come back and do work for us again. There is something about this

place and the people that instill a lasting positive impression on

people."

Thank you TriMark employees for 40 years of loyal and dedicated

service.

To share this article with a friend or colleague, please use the Send

to a Friend link at the end of this newsletter.

|

|

|

|

|

|

|

TriMark Corporation

500 Bailey Avenue

PO Box 350

New Hampton, IA 50659

Tollfree: 1-800-447-0343

Phone: 1-641-394-3188

Fax: 1-641-394-2392

Email: tips@trimarkcorp.com

Visit us on the web at www.trimarkcorp.com

This e-newsletter

is a service of TriMark Corp. and is produced by The Bearings Group

|

|

|

|

![]()